In the world of modern manufacturing, CNC machining has revolutionized the way products are created. From automotive components to aerospace parts, this advanced technology allows manufacturers to achieve high precision, efficiency, and repeatability. Whether you are new to the world of machining or looking to expand your knowledge, understanding CNC machining is crucial for anyone in the manufacturing industry.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computer-controlled machines to automate the production of parts and components. These machines are programmed to perform a variety of tasks, such as drilling, milling, turning, and cutting, with incredible accuracy. The CNC system directs the movement of tools based on a set of instructions provided in a computer program, allowing for high levels of precision that would be difficult to achieve manually.

CNC machines are capable of producing complex shapes and intricate details that were once impossible or too time-consuming with traditional manual methods. This technology has made mass production and custom manufacturing much more efficient and cost-effective, ensuring a high-quality end product with minimal waste.

Types of CNC Machines

There are several different types of CNC machines, each designed to perform specific tasks. Some of the most common types include:

- CNC Milling Machines: These machines are used to remove material from a workpiece to create a desired shape. CNC milling machines use rotary cutters to perform operations like drilling, tapping, and cutting.

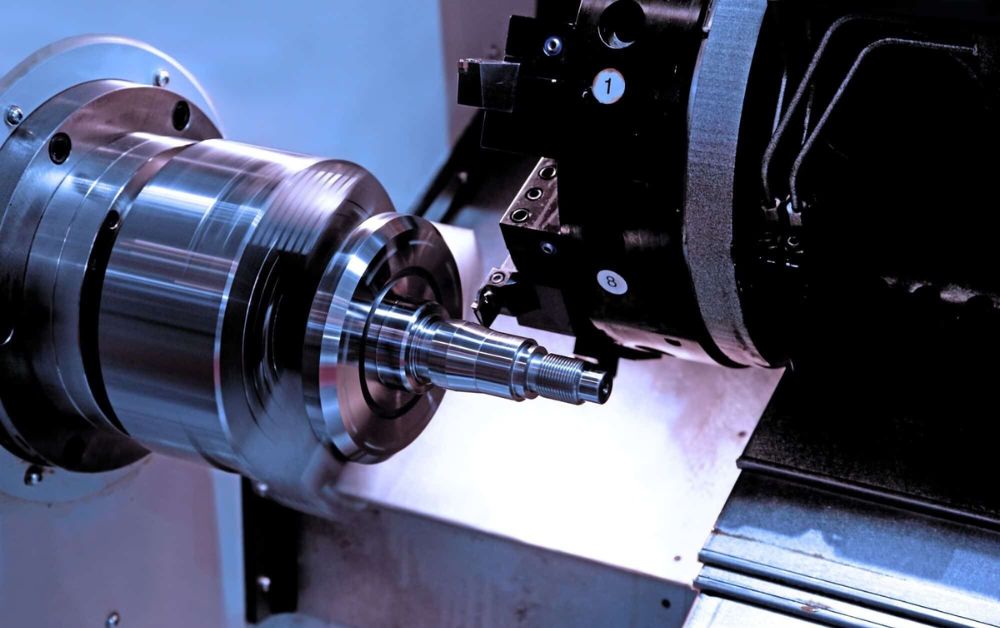

- CNC Lathes: Lathes are used to rotate a workpiece on its axis while a cutting tool shapes it. This process is commonly used to create cylindrical or spherical objects, such as shafts, gears, and other similar components.

- CNC Routers: These machines are used primarily for cutting softer materials, such as wood, plastic, and foam. CNC routers use a spinning tool to carve out precise shapes and designs.

- CNC Turning Machines: A CNC turning machine is specifically designed for shaping cylindrical parts. It works by rotating the workpiece while a stationary cutting tool is fed along different axes to cut, shape, or drill the material. The process is ideal for producing parts such as screws, bolts, and other round objects with precision.

How Does CNC Machining Work?

CNC machining begins with a digital design or CAD (Computer-Aided Design) model. The design is then converted into a set of instructions known as G-code, which tells the CNC machine exactly how to move, which tools to use, and how to manipulate the material. This code is loaded into the CNC machine, which follows the instructions to produce the desired part.

The process involves several steps:

- Design and Programming: A CAD model is created, and the design is translated into machine-readable code.

- Setup: The raw material is loaded onto the CNC machine, and the correct cutting tools are installed.

- Machining: The machine follows the programmed instructions to cut, shape, or finish the material.

- Finishing: Once the part is created, it may undergo additional steps, such as polishing or coating, to achieve the final look and functionality.

Advantages of CNC Machining

- High Precision and Accuracy: CNC machines can produce parts with tight tolerances, ensuring consistent results every time.

- Efficiency: CNC machines can operate continuously and handle high-volume production, making them ideal for mass production.

- Flexibility: CNC machines can work with a wide range of materials, including metals, plastics, and composites, allowing for versatile applications across various industries.

- Automation: The process is automated, reducing human error and improving overall production efficiency.

Applications of CNC Machining

CNC machining is used across various industries, including aerospace, automotive, medical, and electronics. Some common applications include:

- Automotive Components: CNC machines are used to produce parts like engine components, transmission gears, and valves.

- Aerospace Parts: CNC machining is crucial for creating precise components for aircraft, such as turbine blades and fuselage panels.

- Medical Devices: CNC machines are used to manufacture surgical instruments, implants, and prosthetics with extreme accuracy.

Conclusion

CNC machining has transformed the manufacturing industry by providing efficient, precise, and cost-effective methods for producing a wide range of parts. One of the key machines in this process is the CNC turning machine, which is crucial for creating cylindrical and round components with high precision. If you are looking for top-quality CNC machining services, Raysun Techno Industries LLC offers expert machining solutions tailored to your needs. With their advanced technology and skilled technicians, they ensure that each part is made with the utmost precision and care.