Introduction:

In the world of precision machining, the choice between CNC turning machines and manual lathes machines is a pivotal decision. Both technologies have their own merits and applications, and selecting the right one depends on various factors, including the specific requirements of a project, efficiency, and precision. Let’s delve into the distinctions and considerations that go into making this choice.

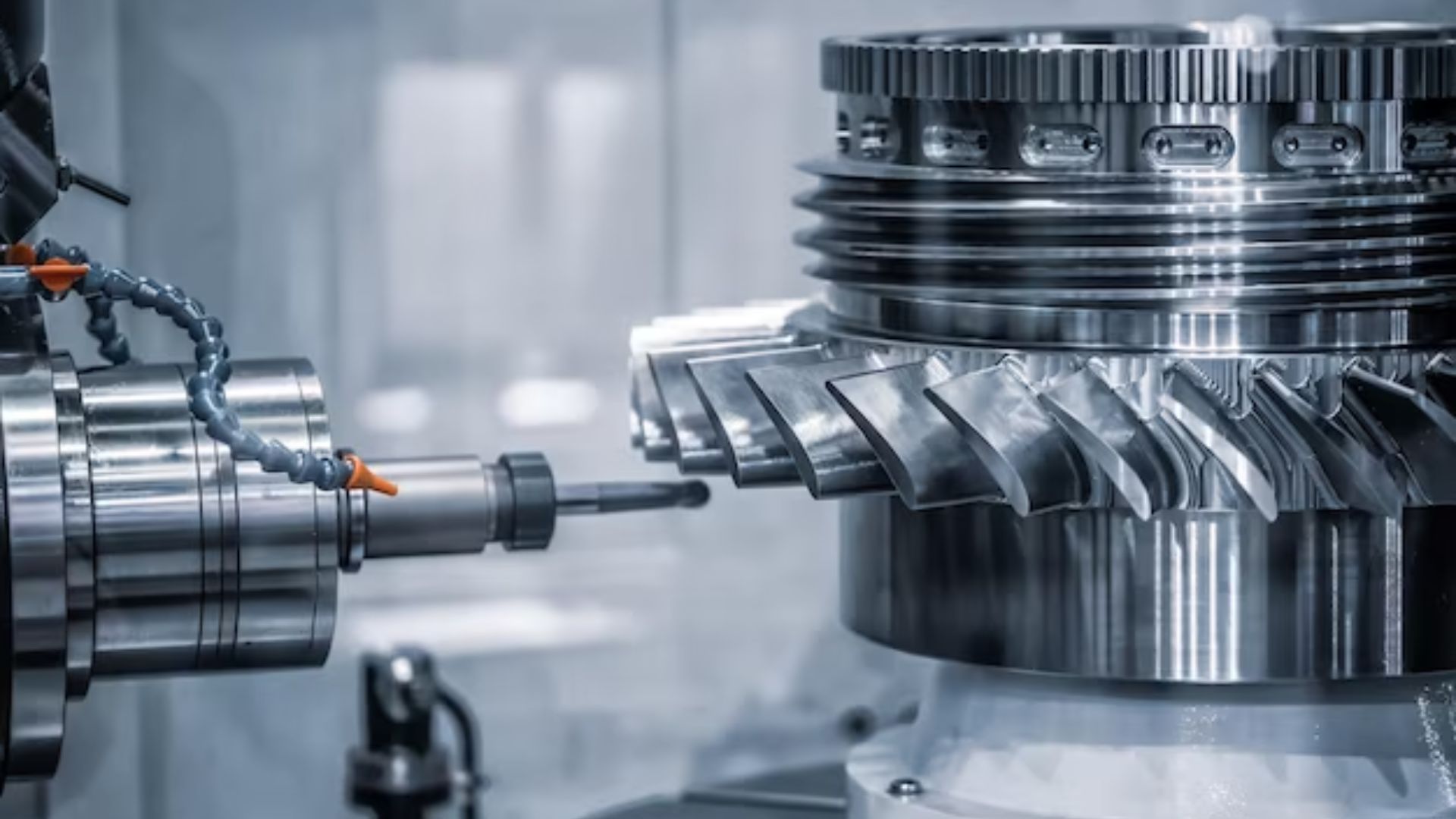

CNC Turning Machines: Precision Meets Automation

CNC turning machines are the epitome of precision and automation in machining. These machines are equipped with Computer Numerical Control (CNC) systems that can be programmed to execute intricate and repetitive tasks with remarkable accuracy. CNC turning machines offer several advantages:

- Precision: CNC turning machines can produce components with incredibly tight tolerances, ensuring that each piece meets exact specifications consistently.

- Efficiency: The automation aspect of CNC turning machines results in faster production cycles, reduced labor costs, and minimal material waste.

- Complexity: They can handle complex shapes and intricate designs that would be challenging or impossible to achieve manually.

- Consistency: CNC turning machines deliver uniform results, eliminating variations caused by human factors.

These machines are widely employed in industries such as aerospace, automotive, and medical device manufacturing, where precision and repeatability are paramount.

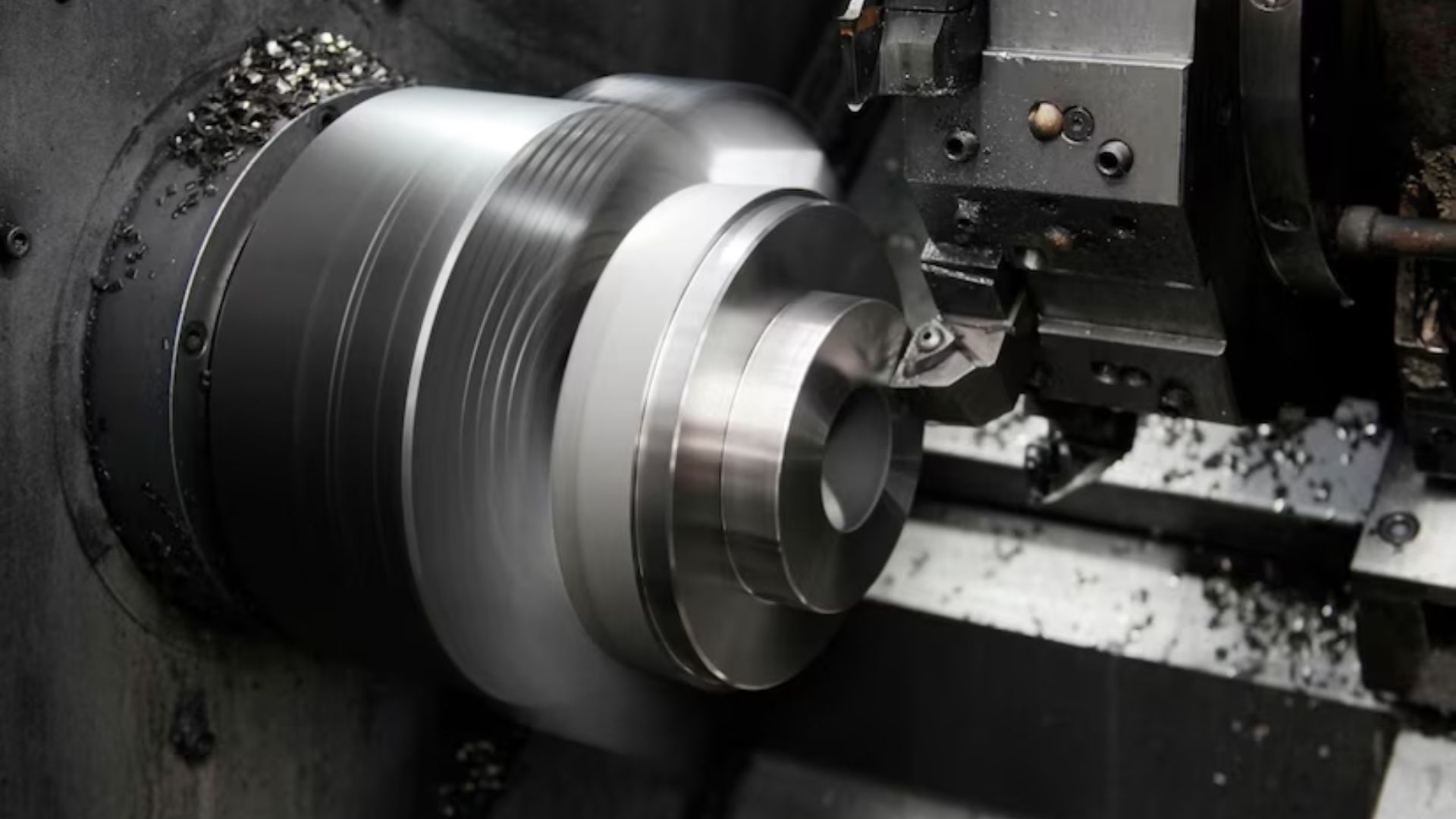

Manual Lathes: Craftsmanship and Flexibility

Manual lathes, on the other hand, rely on the skill and expertise of machinists. Operating a manual lathe machine involves hands-on manipulation of tools and materials. While manual lathes may not match CNC machines in terms of speed and precision, they offer distinct advantages:

- Versatility: Manual lathes excel in handling custom and one-off projects where adaptability and quick adjustments are essential.

- Craftsmanship: Skilled machinists can make real-time adjustments to achieve the desired results, making manual lathes ideal for projects that require a personal touch.

- Affordability: Manual lathes are often more affordable than CNC machines, making them accessible to smaller workshops and artisans.

Manual lathes find their place in industries such as custom fabrication, repair shops, and artistic craftsmanship, where unique and intricate work is valued.

Choosing the Right Solution

The decision between CNC turning machines and manual lathes boils down to the specific needs of the project and the available resources. When choosing, keep the following things in mind:

- Project Complexity: For high-volume production with consistent designs, CNC turning machines offer efficiency and precision. Manual lathes shine when dealing with custom, intricate, or one-off projects.

- Budget: CNC turning machines require a significant upfront investment, while manual lathes are more budget-friendly.

- Skilled Workforce: CNC machines necessitate operators with programming skills, while manual lathes rely on machinists with hands-on expertise.

- Production Volume: High-volume production may favor CNC turning machines, while small-scale production or prototyping may lean towards manual lathes.

Conclusion:

The choice between CNC turning machines and manual lathes hinges on various factors, each with its own set of advantages. Dubai’s diverse industrial landscape benefits from both technologies, as they cater to the city’s diverse manufacturing needs, ensuring precision and flexibility across a wide range of projects. The perfect machining solution ultimately depends on the unique requirements and objectives of the task at hand.