In the world of metalworking, joining techniques like brazing and welding are essential for creating strong and durable connections between materials. Each method has its unique advantages, applications, and suitability depending on the materials being joined and the specific requirements of the project. While brazing and laser welding are both popular techniques for joining metals, they differ significantly in terms of process, materials, and outcomes. In this blog, we will explore the key differences between brazing vs laser welding, and highlight when to use each method.

What is Brazing?

Brazing is a joining process that uses a filler metal with a melting point above 450°C (but lower than the melting point of the base materials). Unlike welding, where the base materials are melted, brazing involves heating the materials to a temperature that is high enough to melt the filler metal but not the base metals. The filler metal flows into the joint by capillary action, creating a strong bond once cooled. This process is often used for joining dissimilar metals and materials that cannot be welded.

Advantages of Brazing:

- Lower Temperature: The process operates at a lower temperature compared to welding, making it ideal for heat-sensitive components.

- Ability to Join Dissimilar Metals: Brazing is often used to join materials that are difficult to weld, such as copper to brass or aluminum to steel.

- Minimal Distortion: Since the base metals are not melted, the risk of distortion is much lower.

- Cost-Effective: Brazing can be a more economical option, especially when working with thin-walled materials or larger parts that would be difficult to weld.

Disadvantages of Brazing:

- Weaker Bond: While the bond created by brazing is strong, it is typically not as strong as a welded joint.

- Requires Proper Cleaning: The joint surfaces need to be clean to ensure a strong bond, as contaminants can weaken the connection.

What is Laser Welding?

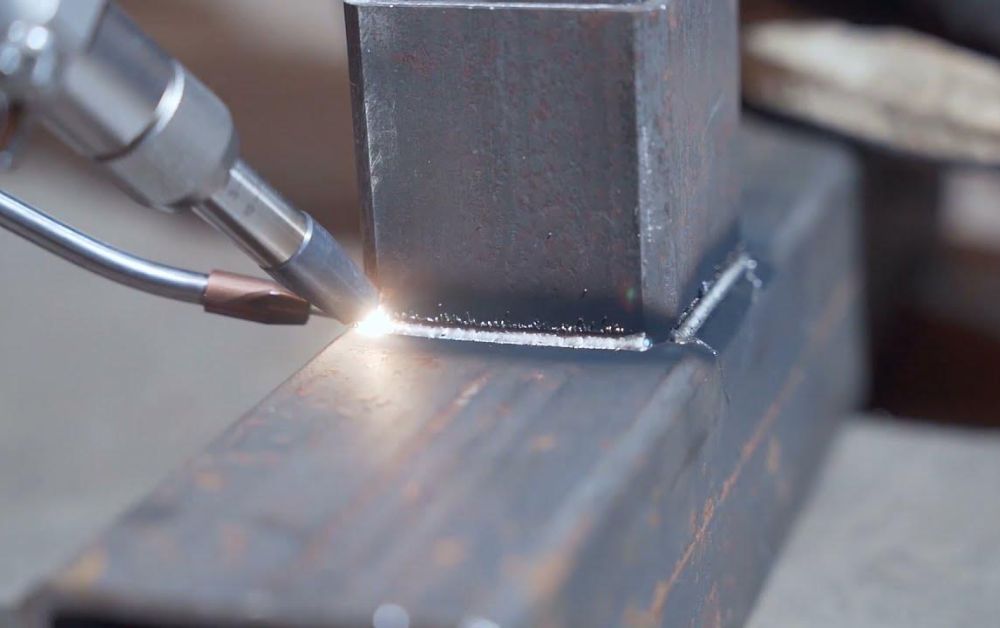

Laser welding is a high-precision welding technique that uses a focused laser beam to melt and join materials. The laser beam generates intense heat at a very small point, which melts the material to create a weld. This method is highly controlled, offering extremely fine and accurate welds. Laser Welding Dubai has become popular in industries such as aerospace, automotive, and electronics due to its precision and ability to work with a variety of metals.

Advantages of Laser Welding:

- Precision: Laser welding can produce highly accurate welds with minimal heat input, making it ideal for intricate designs and thin materials.

- Speed: The process is fast, allowing for high-throughput production and minimizing the time needed for each weld.

- Minimal Heat Affected Zone (HAZ): The laser’s concentrated heat limits the affected zone, which reduces thermal distortion and the need for post-weld treatments.

- Versatility: Laser welding can be used for both metals and plastics, and it is capable of joining materials with varying thicknesses.

Disadvantages of Laser Welding:

- High Equipment Cost: The cost of laser welding machines and maintenance can be high, making it less affordable for smaller operations.

- Specialized Skill: The process requires skilled operators who understand the technology and can manage the complex equipment.

Key Differences Between Brazing and Laser Welding

- Temperature: Brazing operates at lower temperatures compared to laser welding. In brazing, only the filler metal melts, while laser welding melts both the filler and base materials.

- Bond Strength: Laser welding creates a stronger bond since both materials are melted and fused together, while brazing relies on the filler metal and offers a slightly weaker connection.

- Materials: While brazing is effective for joining dissimilar metals, laser welding is better suited for high-precision applications, especially with metals that can withstand the heat required.

- Precision: Laser welding provides a more precise and controlled process with minimal thermal impact on the surrounding area, while brazing is more flexible but less precise.

- Cost: Brazing tends to be more cost-effective for many applications, while laser welding can be expensive due to the high initial investment in equipment.

Conclusion

Both brazing vs laser welding offer distinct advantages, depending on the materials and requirements of the project. Brazing is ideal for joining dissimilar metals and is a more cost-effective solution, while laser welding is perfect for high-precision work with a strong, clean bond. If you’re considering advanced welding or brazing solutions in Dubai, Raysun Techno Industries LLC provides expert services, including Laser Welding Dubai, to ensure top-quality results. Their skilled team is equipped with the latest technology to meet all your welding and brazing needs efficiently and effectively.