Introduction:

Efficiency and accuracy are key in the industrial sector. As industries continue to evolve and demand higher levels of accuracy and productivity, the advent of CNC (Computer Numerical Control) turning machines Dubai has brought about a revolution. These machines have redefined the landscape of manufacturing, offering a level of precision and efficiency that was previously unattainable through traditional machining methods.

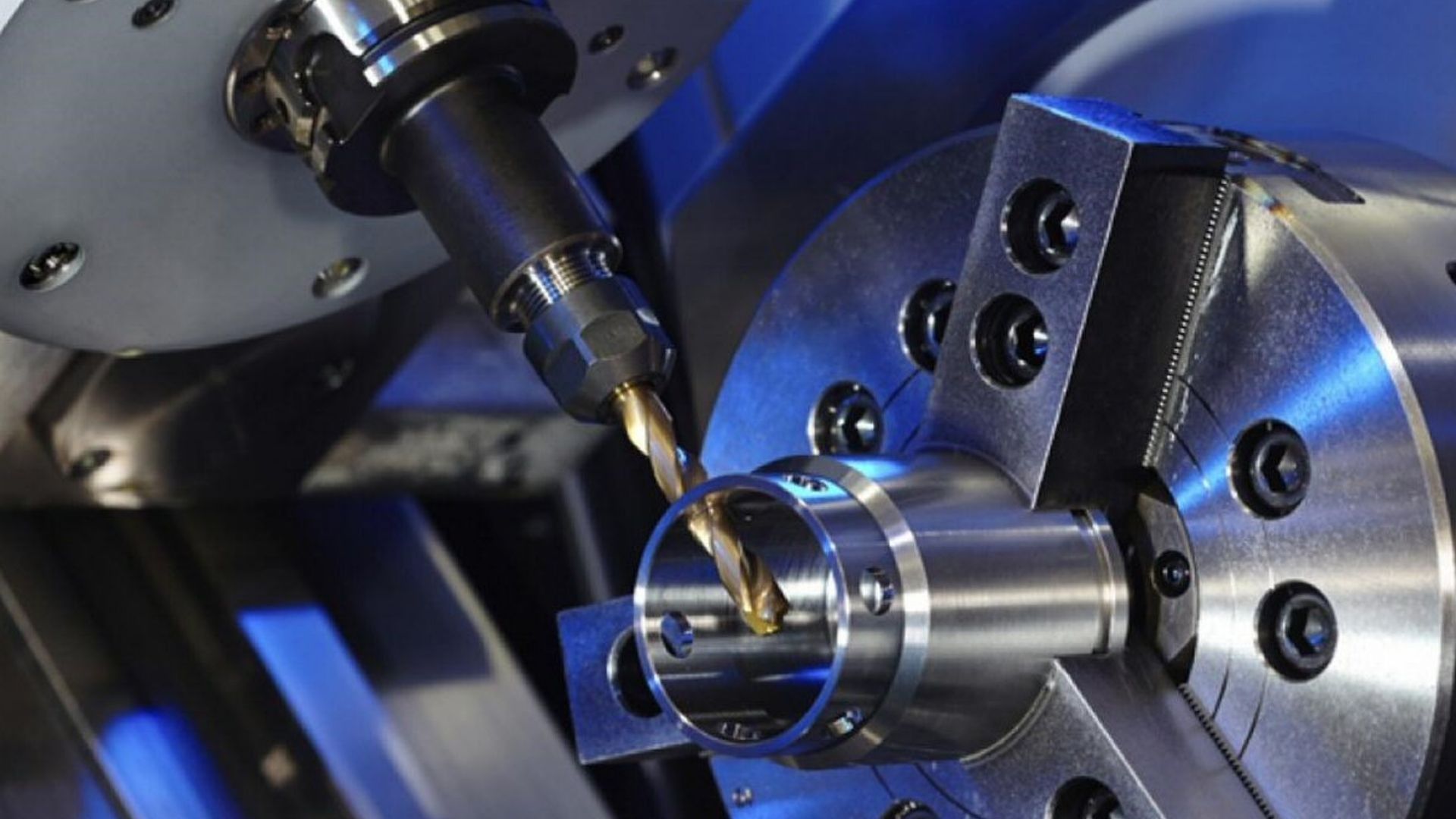

The CNC Turning Machine: An Overview

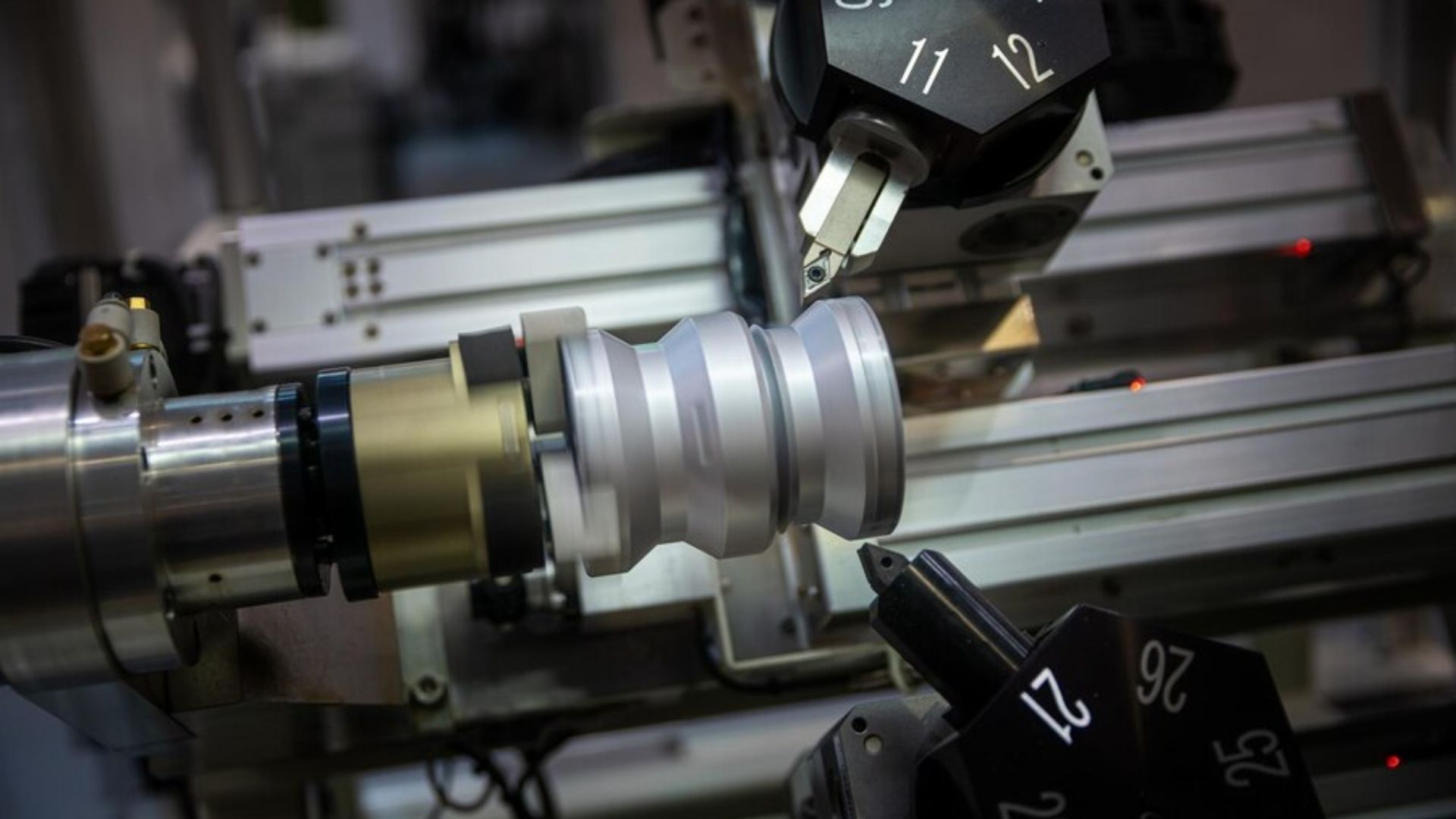

CNC turning machines are a subset of CNC machining tools designed for shaping materials like metal, plastic, and wood. They operate by rotating a workpiece while a cutting tool removes material to create the desired shape. What sets CNC turning machines apart is their ability to execute intricate and complex operations with unparalleled accuracy.

Precision Redefined

One of the standout features of CNC turning machines is their precision. These machines can achieve tolerances in the range of micrometers, ensuring that each part produced meets exact specifications. This level of accuracy is crucial in industries such as aerospace, automotive, and medical device manufacturing, where even the slightest deviation can have serious consequences.

Efficiency and Productivity

Efficiency is another driving force behind the CNC turning machine revolution. These machines can run continuously, 24/7 if needed, with minimal downtime for tool changes or adjustments. Their ability to automate processes, coupled with high spindle speeds and rapid tool changes, results in significantly shorter production times. This translates into increased productivity and cost savings for manufacturers.

Complex Geometry Made Simple

One of the most remarkable aspects of CNC turning machines is their versatility in handling complex geometries. With the aid of advanced CAD/CAM software, manufacturers can program these machines to create intricate parts that would be extremely challenging or impossible to produce using conventional methods. This capability opens up new design possibilities and allows for the production of highly specialized components.

Reduced Material Waste

CNC turning machines are known for their efficiency not only in time but also in material usage. Traditional machining methods often produce a significant amount of waste as excess material is removed to achieve the desired shape. CNC turning machines, on the other hand, are programmed to minimize waste by precisely removing only the necessary material. This aligns with sustainable production techniques while also lowering expenses.

The Future of CNC Turning Machines

As technology continues to advance, so too will CNC turning machines. The integration of AI (Artificial Intelligence) and IoT (Internet of Things) into CNC systems promises even greater levels of automation, predictive maintenance, and data-driven decision-making. This will further enhance efficiency and precision, pushing the boundaries of what is achievable in manufacturing.

In conclusion:

The CNC turning machine revolution has transformed the manufacturing landscape by redefining precision and efficiency. These machines have become indispensable in industries that demand the highest levels of accuracy and productivity. As technology continues to evolve, CNC turning machines will play a central role in shaping the future of manufacturing, offering new possibilities and opportunities for innovation in a wide range of industries.

“Read More and Learn All About CNC Turning Machines on Our Blog!”

2. (The Ultimate Manual Lathe Machine Buyer’s Guide: Dubai Insights)