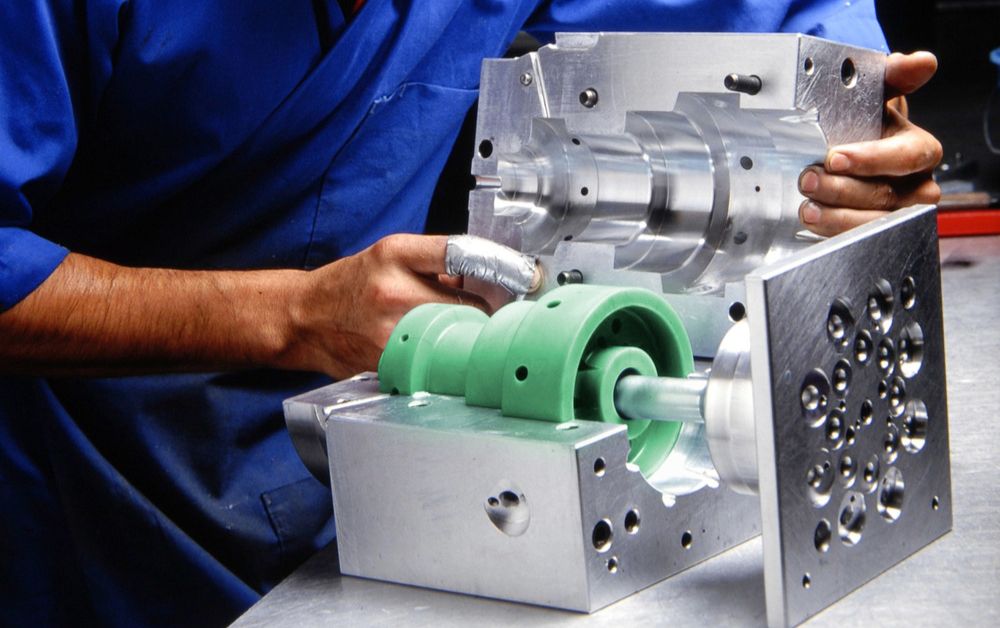

Moulds and dies are essential tools in manufacturing, enabling the mass production of precise components in industries such as automotive, aerospace, and consumer goods. However, due to continuous use, these tools experience wear and damage over time, leading to defects in the final products. This is where CNC machining plays a vital role in precision mould & dies repair, restoring these critical components to their original condition with unmatched accuracy and efficiency.

Why CNC Machining is Essential for Mould & Die Repair

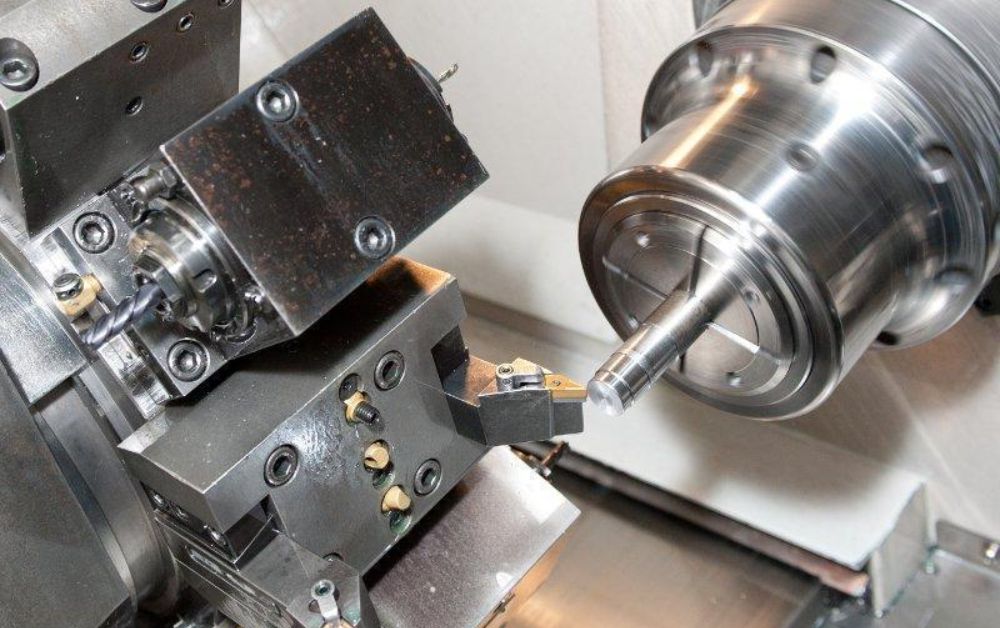

Traditional repair methods often rely on manual techniques, which can be time-consuming and prone to human error. In contrast, CNC machining utilizes computer-controlled systems to execute precise, automated repairs, ensuring consistency and extending the lifespan of moulds and dies.

1. High Precision and Accuracy

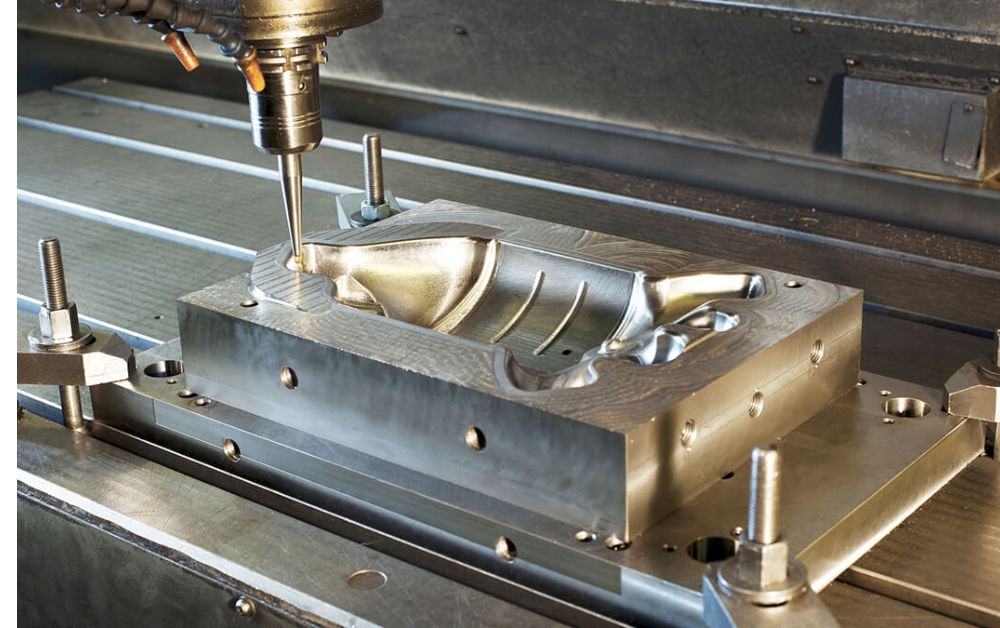

One of the biggest advantages of CNC machining in mould & die repair is its ability to achieve micron-level precision. CNC machines can accurately remove damaged sections, rework intricate cavities, and restore fine details that manual repair methods might struggle to replicate.

2. Faster Turnaround Time

Time is crucial in manufacturing, and downtime due to damaged moulds and dies can lead to production delays. CNC machining speeds up the repair process by automating tool paths, reducing the need for manual adjustments, and enabling faster material removal. This ensures that manufacturers can resume production with minimal downtime.

3. Cost-Effective Repairs

Replacing an entire mould or die can be an expensive process. With CNC machining, repairs can be carried out efficiently, restoring worn-out areas without the need for complete replacement. This helps companies save costs while maintaining the integrity of their production tools.

4. Improved Surface Finish and Durability

CNC machines can achieve superior surface finishes, which is critical in mould & die repair. A smooth finish enhances part quality, reduces friction, and minimizes material buildup during production. Additionally, CNC machining can be used to apply hard coatings or rework surfaces to enhance the durability of repaired moulds and dies.

5. Compatibility with a Wide Range of Materials

Moulds and dies are often made from hardened tool steel, aluminum, and other high-strength materials. CNC machining is highly versatile and capable of cutting, milling, and grinding a variety of materials with ease. This makes it the preferred choice for repairing complex moulds and dies across different industries.

Applications of CNC Machining in Mould & Die Repair

- Reworking worn-out cavities and cores to restore precise dimensions.

- Repairing chipped or broken edges without altering the overall design.

- Resurfacing and polishing to achieve a flawless finish.

- Modifying or upgrading existing moulds to improve performance.

Conclusion

For businesses seeking high-quality mould & die repair solutions, Raysun Techno Industries LLC stands as a trusted name in precision engineering. With advanced CNC machining capabilities and expertise in tool restoration, Raysun Techno Industries LLC ensures that moulds and dies are repaired with the highest standards of accuracy, efficiency, and durability, keeping production lines running smoothly.