TIG is brief for Tungsten Inert Gas, and it is a standard kind of welding utilized for stainless steel, Al, Ti, and different non-ferrous metals.

The arc dissolves a fill bar of metal alloys. The arch, where the electrode is nearest to the metal and the filler rod is neighboured by an inert gas, generally, argon or an argon-CO2 combination to create the weld as robust as feasible.

Solder more metals and alloys than any further procedure

TIG solders can be utilized to weld steel, stainless steel, Chromoly, Al, Ni alloys, Mg, Cu, brass, bronze, and actual gold. TIG welding Dubai is a practical welding procedure for welding buggies, bike stands, yard mowers, doorway holds, fenders, and more.

Produce high-quality, neat welds

With incomparable angle and weld pool management, TIG permits you to form neat welds when impressions matter. Because the warmth intake is often controlled by insisting on a floor pedal, similar to operating an automobile, TIG welding permits you to warm up or chill down the weld reservoir giving you actual weld dot command. This creates a TIG welding exemplar for decorative welds like statues and automotive welds.

No sparks or splatter

Because just the required quantity of contents metal is counted to the welding reservoir, no splatter or sparks are created (if the metal being welded is sterile).

No instability or slag

As the Argon gas covers the weld reservoir from contamination, no instability is needed or utilized in TIG welding, and there is no slag to obstruct your idea of the weld pool. Furthermore, the concluded weld will not have slag to release between weld access.

No steam or fumes

TIG welding does not produce steam or fumes unless the ground metal being welded contains impurities or components such as oil, fat, paint, lead, or zinc.

TIG welding applications

The most essential applications for TIG welding and nonfrictional coating Dubai are channel and tube welding. It is, nevertheless, utilized in numerous industries, such as flight and aerospace, and sheet metal enterprises when soldering thin fabrics and special textiles such as titanium.

TIG soldering is appropriate for both manual and automated welding as well as for operating fusing robots.

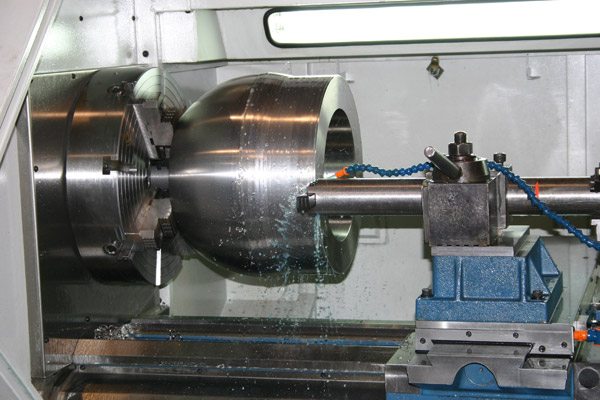

Weld lathe devices

Automated weld lathe machining Dubai is developed and produced for both small and extensive soldering applications. Lathe welders are generally utilized to fuse hems or to link numerous elements together.

Lathe machines’ prominence and advantages

Lathe devices are positively adaptable devices that are utilized to shape intricate elements with extreme accuracy and grade. Therefore, lathe devices are required for manufacturing initiatives. Lathe machines are concerned in different fields that include automotive, flight, therapy, army, etc. Similarly, lathe devices are unexpected to become outdated anytime shortly or even ever, as they are straightforward devices that enact almost most of the required machining procedures.

As the applications and benefits of TIG welding are extensive, Raysun provides a wide array of welding products and processes. If you feel the need to know more, visit our store and website for a comprehensive range of products.