Hardfacing is a specialized welding technique used to enhance the wear resistance and durability of metal surfaces. This process involves depositing a harder or more wear-resistant material onto a softer base metal, extending the lifespan of machinery and components subjected to harsh operating conditions. In industries such as mining, construction, and manufacturing, Hardfacing Welding Dubai solutions are crucial to maintaining efficiency and reducing downtime.

What is Hardfacing?

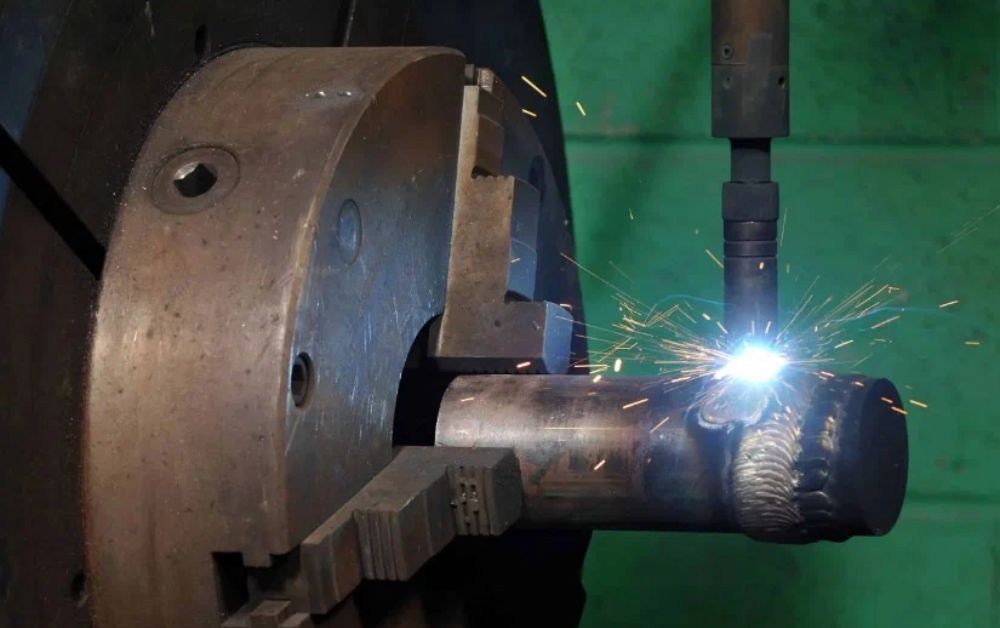

Hardfacing is a form of welding in which a layer of hard material, often an alloy or composite, is applied to a metal surface. The primary goal is to protect the surface from wear, abrasion, impact, corrosion, or heat. This process can be applied to new components to enhance their durability or used to repair worn-out parts, restoring them to their original functionality.

Applications of Hardfacing

1.Mining and Drilling Equipment

Hardfacing is commonly used to strengthen components like crusher jaws, drill bits, and conveyor screws. It ensures these parts can withstand extreme wear and tear in tough environments.

2.Agricultural Tools

Plowshares, cultivator blades, and harvester components benefit from hardfacing, allowing them to endure prolonged use without frequent replacement.

3.Industrial Machinery

Rollers, valves, and pumps in industrial settings often undergo hardfacing to improve their resistance to abrasion and erosion.

4.Construction Equipment

Excavator buckets, bulldozer blades, and other heavy equipment parts are often hardfaced to enhance their performance and longevity.

How Hardfacing is Applied

1.Choosing the Right Hardfacing Material

The choice of material depends on the specific type of wear the component will face. Common hardfacing materials include chromium carbide, tungsten carbide, and other metal alloys.

2.Selecting the Welding Process

Various welding techniques can be used for hardfacing, such as:

Shielded Metal Arc Welding (SMAW): Suitable for field applications.

Gas Metal Arc Welding (GMAW/MIG): Ideal for high-speed, high-deposition applications.

Submerged Arc Welding (SAW): Provides deep penetration for thick deposits.

Plasma Transferred Arc Welding (PTA): Offers precision and control for complex applications.

3.Preparing the Base Metal

The base metal surface is cleaned thoroughly to remove dirt, rust, and contaminants. In some cases, preheating the metal is necessary to prevent cracking during the process.

4.Applying the Hardfacing Layer

The chosen hardfacing material is applied using the selected welding process. Multiple layers may be applied depending on the desired thickness and application.

Advantages of Hardfacing

- Extends the life of components, reducing maintenance costs.

- Improves performance and reliability in demanding environments.

- Reduces downtime by repairing and reinforcing parts in situ.

Conclusion

For businesses and industries looking for efficient Hardfacing Welding Dubai solutions, Raysun Techno Industries LLC is the go-to provider. With state-of-the-art equipment and a skilled team, Raysun Techno Industries LLC delivers superior hardfacing services tailored to meet the diverse needs of industries in Dubai. Whether it’s enhancing the durability of machinery or repairing worn-out components, Raysun Techno Industries LLC ensures excellence and reliability in every project. Partner with them to elevate your operational efficiency and equipment longevity.